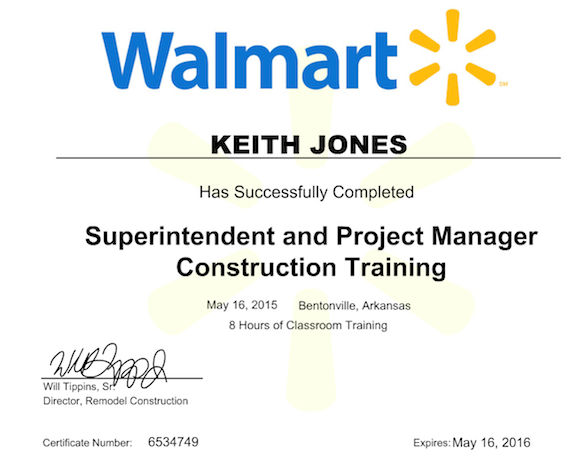

1. My construction work history & certificates

2. A few photos of past projects I want to save.

3. Details of some of my jobs.

4. Some instructional articles I wrote as part of a long term superintendent training program to improve onsite skills.

5.

Ablestik Labs, Rancho Dominguez, 80,000 sq. feet, about $10 million.Special features included a class 10,000 cleanroom and blast-resistant facilities that included explosion vent panels.

The Inn At Laguna Beach was a 90% tear down then entirely new structure that included two levels of subterranean parking. In this photo the room modules on the left are the original building although completely gutted including a new slab. The righthand room area is the new building. On the side opposite the ocean is Pacific Coast Highway. To the right of this building are the famous volleyball courts of Main Beach.

The front end is not so imposing as the oceanside. The parking structure, goes down two levels from the entrance just beneath the Inn At Laguna signage.

Below Award winning East Hills Office Park

John Dominis Restaurant & Marina

Newport Beach, CA

This project was sandwiched between Newport Bay and Pacific Coast Highway.

The basement slab was an immense monolithic concrete pour of 6,800 cubic yards. At that time the largest non-stop single concrete pour ever completed west of the Mississippi River. The weight of the concrete was required to keep the building from floating, since 3 sides and the bottom were actually in the Bay. I could write a book just about that 24 hour concrete pour and the preparations leading to it.

ONE CONSTRUCTION ARTICLE I WROTE

This became part of the superintendent basic operation manual.

From: Keith Jones

Sent: Friday, August 29, 2008 10:32 AM

To: Keith Jones

Cc:

recipients today = 20 superintendents, 7 project managers plus 3 V.P. and President.

Subject: Jonesy's Friday Email -

Helping your sub contractors to succeed

Jonesy’s Friday email – August 29, 2008

Thank you all for attending our special expanded quarterly safety meeting yesterday. I know it is difficult for you to get away from your projects to attend these long meetings. Your positive attitudes and enthusiasm were a nice change from our first meeting a few months ago. At our monthly meetings about half of you are able to attend each meeting, which is satisfactory given how spread out we are right now.

Helping your sub contractors to succeed

Part 1 – more to follow another Friday

One question that comes up repeatedly in my conversations with superintendents is “why is this sub not taking care of me? He is one of our regular subcontractors. He is not performing satisfactorily.”

Of course there are usually several possible answers and causes for the failure of that contractor. Here are some of reasons that problems and issues may arise with a normally reliable sub contractor, along with some hints to help you cut off these problems before they start.

1. The competency and personality of the Foreman. A bad foreman always makes the job bad! Is this guy doing drugs in the portable toilet? Is his beautiful blonde wife divorcing him, dating his best friend and living in the house your foreman is paying for, while not allowing him to see his kids? Was he out drinking last night until the bars closed and then barely got into bed before his alarm went off?

Usually workers who get to the foreman level have shown their boss that they can produce! They pretty much always show up to work on time and then kick their crew in the butts if the crew doesn’t get to work and produce too. But let just one personal problem creep into that guys’ life and he may suddenly become a miserable wreck, maybe while working on your job.

Some guys need money. That pretty wife maybe likes to spend too much money while her husband, your sub’s foreman, is at work earning that cash.

It is not uncommon for foreman to take on “side work”. Sometimes this side work becomes more important than the guys real job. He will be on the phone all day talking to workers on his side job, calling suppliers to order material for the weekend, checking to see if his inspector signed the permit card for the framing on that room addition he has on the side.

Or you may find him talking and whining to his client as he explains why he won’t be back to that side job on Saturday, when the real reason he won’t be there is because he is needed on your job. So he ends that phone call pissed off at you, because you are forcing his crew to work Saturday. Without knowing it, you have got into his pocket and are costing him money and good will with his side job client. Is this your fault? Of course not. Is this your problem? We all know that it if he doesn’t do his job right, whether for this or for some other reason, it will surely become your problem to solve in the end.

If you recognize that you have a problem foreman on your hands, you may need to get him moved off of your job. That is not always easy. It should never be attempted by using aggressive actions. If you need or want a foreman removed, your best chance to do this is to gather your reasons and then discuss the situation with your project manager. Together you can present a united front to the sub contractors’ project manager or owner. Together you and the PM working as a team, can give the foreman’s boss a clear and logical explanation of why the change needs to take place.

One thing you can be certain of. The sub contractor will at first resist making the change. The better your background information and the more rational and calm your presentation, the more likely you are to succeed.

2. The sub suddenly has too much work. None of us want to say no to a contract. Subs bid projects by the hundreds, then they forget about them until they receive a call saying they got the job! Sometimes a “GOOD” sub will analyze their schedule, then tell our PM that they can handle the project, but not during a certain time period because they are already over-committed for that specific time period. Then maybe all parties agree that the work of this sub contractor will be done before that critical time.

Contracts are signed and then there are delays in starting up our project. Eventually when the job begins it is at the very time this sub knew he had a manpower problem. There are many possible scenarios why a sub-contractor is too busy. Just because he has taken on too much work, does not mean he is a bad sub or even that he knew he wouldn’t be able to service us properly. We all need to keep that in mind when dealing with them. Don’t assume the worst about the sub contractor. Try to discover why there is an issue. If problems develop deal with them calmly and professionally.

3. The sub loses some key employees. Many times a sub contractor has only 1 to 3 key men who run his field crews for him. He, the owner, is busy bidding work, meeting clients, driving to problem job sites to see why the general contractor’s superintendent doesn’t have work areas ready when they are supposed to be ready, picking up plans and doing all those things that a “sub” must do. Losing a key field employee can virtually cripple some smaller companies until they get their crew set up with a new Key Foreman.

4. Material deliveries don’t occur as promised. The sub is at the mercy of his suppliers, just like we are. Really good sub contractors, just like really good superintendents, will check on their critical material deliveries several times before the “due date”. A phone call every couple weeks early in the project, just to make sure the material is still on schedule can prevent lots of headaches later. Some subs are good at this type of tracking of supplies and some are not so good at it. Just like some superintendents are good at that and some are not so good about making those early phone calls.

This question “why isn’t he taking care of me?” has dozens of possible answers. Here is one issue that we can work on to HELP THE SUB CONTRACTOR SUCCEED.

By contacting the sub contractor early in your project and letting him know he needs to order some special material you are helping that sub contractor to succeed. You need to review and identify all the material that may cause problems to your schedule when you are first setting up your project. Then pursue those items with the various sub contractors. Don’t have a contract or sub contractor yet? That’s an entirely different topic and so I won’t discuss that issue here. Make a follow up call one or two weeks after your first contact with the sub to check and verify that A. The material was ordered. B. The material is on schedule to arrive on a specific date. And get that date from the sub.

The subcontractor may act as if you are being a pain in his butt, but without his knowing it, you are helping him to succeed on your project.

Does it feel as if you are doing his job for him? Maybe. But if the end result is a trouble free delivery, then you have succeeded. And isn’t it interesting that almost nobody will know the huge effort that you went through to make that particular material or installation a non-issue! But if you hadn’t made that effort who knows what the results would have been. I know for certain that I have seen too many of our projects dogged by late material deliveries of some special material that was not available in the local distributors warehouse. As deb Construction continues on the path of handling more projects for non-Bank of America clients we will encounter more and more specialty items that require special attention from the very beginning of your project. Help the sub contractor succeed by making these phone calls.

Another common problem or cause of failure of a sub contractor is inadequate communication prior to the sub starting work on the project. It is all too common for the Superintendent to “assume” that the sub knows what he is doing and will come out to the job prepared to do his work.

That is seldom the case. If you haven’t consulted with them ahead of time, expect the UNEXPECTED.

If you are a good superintendent, doing your job properly, then before that subcontractor’s crew arrives on your project site you will have made at least one and probably several phone calls to the sub. These calls are the time to discuss what manpower they will provide at the beginning, equipment, special access they might need, which work area to begin in, their work sequences, material deliveries, inspections and all the issues you must handle with each sub. Commonly a pre-start meeting with the sub contractor takes place and if you are prepared to ask all the right questions at this meeting, you can eliminate the potential problems later when the crew shows up to work.

I urge you to follow up any such a conversation with a brief email to the person you talked to. State simply, but accurately what topics you discussed, any questions that were answered or not answered and especially any important schedule milestones or unresolved issues. You would of course cc your Project Manager with that email and I would like to get a copy as well, so I know what planning you are doing on your projects.

If you feel typing such a response will just take you too long, then I urge you to get on the telephone with the PC of your project and ask for their assistance. You can dictate a letter to the PC or you can handwrite the note and ask the PC to “formalize” it for you. I would not want this to be a daily occurrence, but on specific cases where the telephone conversation was important this is a possible way for those of you who are keyboard challenged to get the job done properly and quickly.

What else can you do to help the sub contractor succeed? What about asking exactly what work they hope will be complete when their crew arrives. For instance, your fire sprinkler sub may want T-bar up before his crew begins work. OR the sub may want to get his crew in before any T-bar is put up. Either way is a possibility depending on the job conditions and the specific sub contractor. A phone call or pre-start conference should clarify this issue so you don’t get started with a misunderstanding before the sub has even begun work on the project.

Another important task you should consider with all sub contractors is to do an initial review of the scope and extent of the work with the job foreman. Together at this job start up meeting you can do a brief review of the plans, asking for specific issues to be brought up. This meeting is the appropriate time to discuss your expectations with the foreman. Schedule, work sequence and safety are all issues that should be discussed. A discussion about special order material needs to take place, although most of the time the foreman won’t know anything about material deliveries until a day or two before the delivery.

This is the first of a multiple part discussion about “Helping your sub contractor to Succeed”. Comments or suggestions for the remainder of this discussion are welcome.

Keith Jones

A brief note about this webpage. I'm actively seeking a

construction management job in the USA. I would consider other

countries, but I'm probably done with warzones. In a formal

resume you, as a prospective employer, cannot get a real feel for what

type of individual you are reading about. On this webpage you will see

some references to non-construction non-engineering related

topics. As I complete this page some of my construction related

articles will be placed online here. Currently one article about

daily report writing is posted down toward the bottom of this

page. I prefer west coast or southern coastal regions and the

majority of my construction projects have been built in

California. Most recently I've working in Afghanistan, Thailand

and the Philippines.

Summary of Construction Employment

Louie Louie’s Espresso Design & Construction consultant – Philippines – Develop franchise construction

Bar, 2013 - 2014 and equipment standards. Supervise construction of first two model stores.

Exception Construction Senior Project Manager – Afghanistan – contract & consultant position

2009 - 2014 Military projects on Kandahar Air Base and some F.O.B. bases.

Deb Construction Director of Field Operations – California G.C. a bank and hospital specialist.

2008 - 2009 scroll down for a detailed description of my position with this company.

TMC Construction Superintendent – Engineering Dept. Mgr. - Construction Operations Manager

2004 – 2007

Public Storage Inc. National Senior Project Manager, retail and commercial self storage projects. Managed 3

2000 - 2003 Project managers & 1 superintendent to build about 50, multi-million dollar projects annually.

Sonora Convalescent Superintendent, 120 bed convalescent hospital, OSHPD permitted project from ground

Hospital 1999 - 2000 breaking to opening of the hospital.

Davcon Inc. Superintendent, promoted to Field Operations Manager directing all superintendents.

Managed dozens of commercial projects primarily mid-rise buildings to 11 floors.

Koll Company Superintendent 1 major multi year project plus hundreds of T.I. projects.

Home Savings Corporate Headquarters project plus many tenant improvement projects.

Credentials & Education

LEED AP Green Building Council accredited

CIPM Certified International Project Manager

Member Society of American Military Engineers

California B1 General Contractors license (in the past I also held roofing and electrical contractor’s licenses)

Graduated BA Architectural Design, Pacific College of Art and Design

AA Civil Engineering ICS Technical College, not completed

OSHA safety certificates 10 and 30 hour & OSHA 510 certificate working toward OSHA 500

First aid & CPR certified

Bilingual capabilities: I speak conversational Spanish

Countries outside USA in which I have been involved in construction projects:

Afghanistan: A series of military projects that included a helicopter landing and refuel base, communications headquarters, perimeter security development, closed area de-mining to make areas usable, on site camp Conex facilities for other contractors.

Mexico: Residential home construction. Seasonal camp resort.

Canada: Public Storage self storage projects as senior project manager and direct project manager.

Thailand: Residential home construction.

Philippines: Restaurant franchise development and construction. Bamboo hut of superior style and design.

Summary of Construction Employment

Louie Louie’s Espresso Design & Construction consultant – Philippines – Develop franchise construction

Bar, 2013 - 2014 and equipment standards. Supervise construction of first two model stores.

Exception Construction Senior Project Manager – Afghanistan – contract & consultant position

2009 - 2014 Military projects on Kandahar Air Base and some F.O.B. bases.

Deb Construction Director of Field Operations – California G.C. a bank and hospital specialist.

2008 - 2009 scroll down for a detailed description of my position with this company.

TMC Construction Superintendent – Engineering Dept. Mgr. - Construction Operations Manager

2004 – 2007

Public Storage Inc. National Senior Project Manager, retail and commercial self storage projects. Managed 3

2000 - 2003 Project managers & 1 superintendent to build about 50, multi-million dollar projects annually.

Sonora Convalescent Superintendent, 120 bed convalescent hospital, OSHPD permitted project from ground

Hospital 1999 - 2000 breaking to opening of the hospital.

Davcon Inc. Superintendent, promoted to Field Operations Manager directing all superintendents.

Managed dozens of commercial projects primarily mid-rise buildings to 11 floors.

Koll Company Superintendent 1 major multi year project plus hundreds of T.I. projects.

Home Savings Corporate Headquarters project plus many tenant improvement projects.

Credentials & Education

LEED AP Green Building Council accredited

CIPM Certified International Project Manager

Member Society of American Military Engineers

California B1 General Contractors license (in the past I also held roofing and electrical contractor’s licenses)

Graduated BA Architectural Design, Pacific College of Art and Design

AA Civil Engineering ICS Technical College, not completed

OSHA safety certificates 10 and 30 hour & OSHA 510 certificate working toward OSHA 500

First aid & CPR certified

Bilingual capabilities: I speak conversational Spanish

Countries outside USA in which I have been involved in construction projects:

Afghanistan: A series of military projects that included a helicopter landing and refuel base, communications headquarters, perimeter security development, closed area de-mining to make areas usable, on site camp Conex facilities for other contractors.

Mexico: Residential home construction. Seasonal camp resort.

Canada: Public Storage self storage projects as senior project manager and direct project manager.

Thailand: Residential home construction.

Philippines: Restaurant franchise development and construction. Bamboo hut of superior style and design.

|

This is just one of my three published books. Titles of my other books are: |

|

|

Deb Construction Position details

Director of Field Operations

2008 - 2009

A 35 year old family owned company that had increased in size in just 3 years from $10 million to over $100 million in 2008 sales. The company had outgrown it’s management's ability. This family run operation needed outside expertise to improve the quality of the operational side of the business, both PM & site superintendent and union trade staff. Prior to 2005 the company was predominantly an interior tenant improvement build out contractor. The change to new construction required major revamping of the corporate project management program. I was responsible for developing training programs in computer software such as scheduling and estimating. I developed a new corporate safety training program. Implemented strategies for managing projects that are more in line with modern business practices. In 2008 to match increases in business volume I increased the field staff by 50% to meet increased sales, while maintaining overall corporate control and without increasing the number of project managers. Through a collaborative team building effort I was able to increase productivity of individual Project Managers by upgrading the skill levels and abilities of the superintendents. With Superintendents handling more paperwork that PMs had been doing this freed up PM time that in the past was being used to micro-manage field activities, that were well within the capabilities of well trained site superintendents. We managed this increase in staff while increasing both profitability and the quality of completed projects. Much of the work performed by Deb Construction was remodeling or renovation of existing bank branches. This work was performed exclusively during off banking hours and with the criteria always present that not one DUST MOTE from our work could be allowed to settle on desks or other surfaces. If any bank employee came in to work and brushed against some surface that left dust on their black or blue suit, a major client issue would result. If any project was ever completed late, it would have been a cause for review of the company position on the select contractor list. While I worked at Deb Construction, completing more than 150 projects ranging from ATM installations to new building construction, no project was ever completed late. Every project was "scored" by the bank construction management firm and the direct bank project manager. Our competition typically scored 85 to 95% on these score sheets. We only accepted 99% or better as an acceptable score from our superintendents. This required my personal inspection of every project weekly, plus my final inspection a couple days before the turn over and scoring assessment. My successes in this postion included achieving a 100% success rate for on schedule project completions based upon more than 150 projects ranging from $300,000 to $20 million in size. Another significant success was to achieve a 22% net profit margin on all projects completed in 2008. We achieved this very nice profit while maintaining and building superior client relations. I instructed scheduling classes for MS Project for Project Managers, Project Engineers and Site superintendents. Before my arrival site superintendents did not develop or maintain the project schedule. Most did not know how to make any changes or updates to a schedule file. That was a task for the PMs only. I changed that procedure and educated the superintendents in the use of software to develop and maintain the project schedule. I also provided one on one mentoring about real life techniques for forecasting site work activities accurately. I instituted the corporate LEED AP study program that helped 80% of our Project Managers, 50% of Project Engineers and 25% of superintendents achieve the LEED AP rating during my tenure. As corporate safety manager for the company I succeeded in bringing the accident ratio down from 1.2 to .8 & in one year placing the company into the top 20% of general contractors with the best safety records in California. My responsibilities included hiring, training and supervising up to 25 site superintendents in two offices, one in Northern California and one in Southern CA. By the end of 2008 with my knowledge of healthcare construction and the introductions provided by the marketing manager, the company had gained new clients in healthcare and critical data facilities. This new work came to comprise 15% of the business mix by the end of 2008. We were awarded and successfully completed our first healthcare related project for Hoag Hospital and the first critical data facility project for REI in Seattle, both shortly before I was laid off. The U.S. economic slow down & especially in banking has brought this business near to closing. My position was eliminated because of the slowdown. |

I'm working on placing detailed job descriptions for my other projects on this website soon. But you can always call or send me an email. PHONE in USA: 1-562-889-4016 |

| Davcon Inc. Position details I started at Davcon as a construction superintendent, hired to manage critical schedule projects and high visibility projects. Bob Lewis a senior V.P. at Davcon was my V.P. project manager when I was a superintendent previously at the Koll Company. When Davcon grew into a position where their projects were beyond the comfort level of their existing 15 superintendents, Lewis asked me to leave Koll and come to work for him. The promise of a smaller, more people oriented company along with the promise of full charge on site responsibility for large iconic projects was too good to pass up. After 3 years Davcon promoted me to the position of General Superintendent (like Field Operations Manager) responsible for the 10 to 20 superintendents. Along with this added responsibility I continued to be the superintendent on the largest most complex projects that Davcon built. I was able to use new hire superintendents as my assistant superintendent or second super. and to train them to our standards. This job ended during a construction recessionary period when the two partners, David Conover and Jim Egner decided to pursue different career goals. My first project for Davcon Inc. ROCKWELL ELECTRONIC DEFENSE B-1 Bomber support group 210,000 square feet of interior and exterior building improvements, including structural and architectural face lift of the exterior, 85,000 square foot mezzanine, elevators and laboratories. Many high tech electronics labs and computer labs. Most were top secret and while I built them, I have little idea what the scientists did after I left. I then built the Inn at Laguna and the John Dominis restaurant and Marina projects. These two projects were both seaside multi level projects with significant subterranean work. They were in different cities but both were located between Pacific Coast Highway and the ocean, making the working conditions difficult and highly politically charged. Then I built LEADING SYSTEMS: Predator Drone research and manufacturing facility. Another military air oriented project while at Davcon was this new manufacturing and research facility that was built to facilitate this company's growth in this mysterious airplane. At the time I had never even heard of drone war airships. During my tenure at Davcon I also completed the Galassos Bakery near Ontario, California. The Household Finance Regional Offices in Pomona was a turnkey new tilt up two story project with 200,000 square feet of office and computer data completed in a rigorous schedule to meet client lease conditions. Other projects included a new MRI imaging building at the Pomona Hospital, four story office tilt up project that featured the tallest tilt up panels ever designed and constructed up to that time with roughly 70 foot tall panels. |

|

| This

article below was written to help create good detailed job reports from the

20 +

superintendents I supervised. These supers were working on Bank

projects primarily for Bank of America and Washington Mutual with some

other smaller banks on occassion. Some critical data center

projects and smaller renovation of hospital projects were also

ongoing. These Jonesy's Friday emails were gathered into a book

that became the basic superintendent training manual. Subject: Elements of a good daily report I’ve been reading every daily report written by each of our superintendents for two weeks now. I think it is time to make some comments about the reports you are turning in to your PMs. The most obvious area that needs to be improved upon is writing enough detail. Most of you write these daily reports as if words are priced by the letter. Even though you may have to hunt and peck to type the report, please remember that these reports are the primary documentation of the day to day activities on your project site. They should give the reader a good idea of what took place at your project site each day. Your attention to making your reports more professional will be a benefit to all of us. And of course, as always, if you have questions or comments you can email me, phone me or talk to me when we meet out on your project site. Elements of a good daily report 1. Clear explanations of special occurrences. This is possibly the single most important element of a good daily report. 2. Accuracy and conciseness: Be accurate, don’t write more than needed, but write all that is needed to document the activities of the day. The reader needs to understand what you are telling him or her. 3. Completeness - - Don’t speculate or write gripes on daily reports. Do that in separate notes to me or to your PM. The daily reports should be written with the approach that they could become documents in a court case. If you have a particularly difficult, urgent or bad situation take place on your project you need to document that issue completely. The proper place to do this documentation would be in a separate written memo or note to your PM or to me. Your daily report might have a simple one or two sentence note regarding this serious issue stating, “An issue between a deb Construction sub-contractor and a bank vendor took place this morning. I intervened, but there were words exchanged between the two men involved. See my memo dated 10-12-08 that goes into detail about this situation”. If this issue is complicated or will require a written explanation that is too long for you to type or to handwrite yourself, then you should ask me for assistance. I will gladly help you draft the note when I am out on your job site that week. I am fortunate to have learned to type fast while still in high school and so I can use a keyboard to quickly assist you in putting together a lengthier explanation about some important issue. 4. Attention to detail - - The superintendent should know more about the project site than anyone else. If someone says “I wonder where the shut off valve is located for that device?” I would expect the superintendent to know exactly where it is. . . in the ceiling – outside – under a counter? Mention special or unusual job details or installations that are taking place that day in your report. 5. Consistency – fill out the same data, the same way each time, from day to day. This provides ease of comprehension for the reader. Then when you make changes to the normal routine they stand out to the regular readers of these reports. 6. Describe coordination problems on the daily report. If a bank vendor shows up and the project was not ready for them, you should note this. You should also mention why they came out if we were not ready for them. Perhaps we were not informed about their schedule. Perhaps you talked to their office, but they ignored your advice about the schedule. Whatever the reason for this coordination problem, you should write an accurate explanation so that your PM knows what to expect. Identify the sub and if possible how many people and what equipment/material they brought with them. 1) Daily reports begin with standard, basic information. You should fill these basic details out daily. The basic information includes job site details and weather details. Weather details are important for such obvious reasons as possible delays to the project. Other reasons that weather might be important later is if there are warranty or defect issues and weather might have affected the installation or application of the product. Examples of this? If it is too cold, some caulking and paint should not be applied. Millwork brought into a project and installed without acclimation might be affected by excessive humidity in the project site. Freezing weather requires special consideration for placement of concrete. Inside and outside temperatures may be important. You decide and comment accordingly. However, it is always pertinent if there is foul weather outside and this should be commented upon. 2) deb employees: Be detailed here. Why are we using deb labor? Is this something that requires action, such as the project manager charging a sub for the labor because of clean up or other back charge issues. I have noticed that on many daily reports the deb employees are listed, but details of their work activities are sparse or missing. If we are self-performing the framing – say that. If the labor was there to sweep, then say that. 3) Material: This entry is intended to track material arrivals at the site. Take note of all materials delivered and used. If there are owner furnished materials just dumped on your site, then this is IMPORTANT to document completely. Say when the material or equipment arrived, where stored and who used them. 4) Visitors: As the superintendent you should know who every person on the job site is. Under “visitors” also include architects, engineers and public inspectors. You should note these visits and document conversations if anything is discussed which changes or clarifies RFIs or contract documents. 5) Safety: Under “did job site inspection”: It is your responsibility as the site construction superintendent to do a site job walk every morning! Just note that you did this job walk, unless something unusual is uncovered during the walk. 6) Subcontractors: This area also should include informational entries for our vendors – such as fire extinguisher delivery etc.- and also for special inspectors such as welding inspectors or concrete inspectors and for outside vendors sent by the client. You would document what they inspect or what work they observe and comment upon it. PLEASE NOTE: Any special inspectors should leave you a daily report of some type. Do not let them leave your jobsite without obtaining the report. Surveyors should always leave you a cut sheet. Before they leave, you should take a minute to review their cut sheet and make certain that you UNDERSTAND exactly what the cut sheet shows! For every entry under this heading you should DETAIL the work accomplished that day. Simply stating “installed light fixtures all day” is not a satisfactory entry under “electrical sub contractor”. That entry should have stated : “2 electricians installed light fixtures in the break room. 1 electrician worked on outlets in the cash room”. Or similar notations This concludes part one of a multi-part Jonesy’s Friday Report targeting daily report writing. Thanks to all of you for getting into the spirit of good report writing. |

|

This is my personal construction oriented page. If you are looking for information about whale watching trips please go to www.bajajonesadventures.com webpage.  |